Two-Color Paste Filling Machine

Single Splitted Hoppers: Single hopper with 2 section for each paste, ensuring that the two different pastes are kept distinct until filling.

The Fully Automatic Tube Filling Machine is equipped with a single hopper divided into two sections, each dedicated to a different paste. This design ensures that the two pastes remain separated until the exact moment of filling, maintaining their distinct properties.

Precision Nozzles: Specially designed nozzles to fill two colors simultaneously without mixing, ensuring a clean and distinct pattern.

The machine is fitted with specially designed nozzles that precisely fill two colors simultaneously, ensuring a clean and distinct pattern with no cross-contamination.

Adjustable Ratios: Capability to adjust the filling ratios between the two colors to achieve the desired effect.

Operators can easily adjust the filling ratios between the two colors, offering flexibility to achieve the desired product effect, making the machine ideal for versatile Tube Filling Sealing Machine operations.

HMI for easy Settings: Our secure HMI can be integrated with external systems for a complete control of the filling even from outside the Clean Room.

The Human-Machine Interface (HMI) on this Laboratory Paste Filling Sealing Machine is user-friendly, allowing for seamless integration with external systems. This feature provides complete control over the filling process, even from outside the clean room, enhancing operational efficiency.

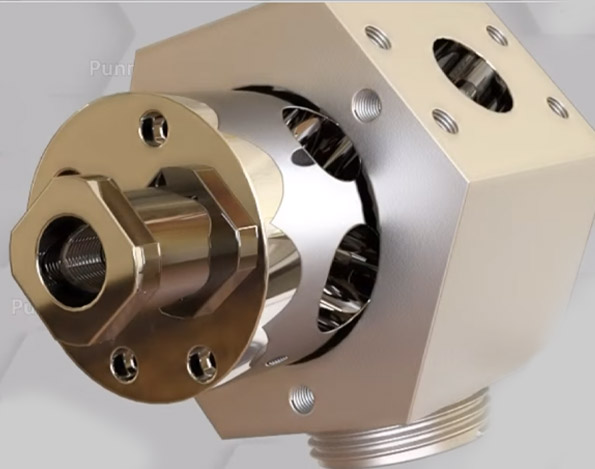

Easy Clean Filling Head: Perfectly designed filling head reducing the hardship in the removal and cleaning of the filling system. The filling system and be cleaned and re-attached with minimal down type in production.

The design of the filling head allows for easy removal and cleaning, reducing downtime and ensuring the machine's longevity. This feature makes the PN-X-01 a low-maintenance solution within the Fully Automatic Tube Filling Machines category.

Low Noise: Our machines reduces the noise decibals in the working place making it comfortable and reducing the labour stress.

Operating at low noise levels, this Fully Automatic Tube Filling Machine creates a comfortable work environment, reducing labor stress and contributing to a better overall production experience.

+61 402 955955

Benefits

Consistency and Quality

Ensures precise and consistent filling, reducing waste and maintaining high product quality.

Regulatory Compliance

Meets stringent industry standards for manufacturing practices, ensuring product safety and regulatory compliance.

Reduced Downtime

Quick changeover capabilities and user-friendly interface minimize downtime during product switches.

Enhanced Product Presentation

Ability to fill two different colors or types of paste simultaneously, enhancing the aesthetic appeal of the product.

Applications

Pharmaceutical Industry

Filling of topical medications, ointments, gels, and creams in various tube sizes.

Cosmetic Industry

Packaging of skincare products, lotions, hair care products, and other cosmetics.

Food Industry

Suitable for filling edible pastes, gels, and sauces.

versatility and efficiency

A fully automatic two-color paste filling machine is a versatile and efficient solution for industries that require the simultaneous filling of two different pastes. Its advanced features, including precise filling mechanisms, user-friendly interface, and compliance with industry standards, make it ideal for applications in the cosmetic, food, and pharmaceutical industries. Pn-X-01 can significantly enhance product quality, production efficiency and overall operational effectiveness.

The PN-X-01, a Fully Automatic Two-Color Paste Filling Machine, exemplifies versatility and efficiency, making it an indispensable tool for industries requiring simultaneous filling of two different pastes. This machine is meticulously engineered to meet the high demands of modern production environments, where precision, reliability, and speed are paramount.

This Automatic Paste Filling Machine stands out with its advanced features, designed to streamline production processes while maintaining the highest standards of quality. The machine's precise filling mechanisms ensure that each paste is dispensed accurately, preserving the integrity of the final product. This capability is crucial for industries like cosmetics, food, and pharmaceuticals, where product consistency is non-negotiable.

The PN-X-01 is not just a machine but a complete solution, providing users with a machine option that is both user-friendly and compliant with rigorous industry standards. Its intuitive interface allows operators to easily control and adjust the filling process, reducing the potential for errors and ensuring smooth operation.